|

Chongqing New Maritime Import&Export Co.,LtdWe are a very professional manufacturer and exporter in marine equipment field , we can customize the goods according to your drawing. |

||||

| Model No. | PE004-020 |

| item | plastic floatiing pontoon |

| material |

LLDPE |

| color | black, blue |

| size | 110x50x50cm, customized |

| type of molding | rotational moulding |

| special features | super high strength, light in weight, anti-corrosion, durable, customized shape, acid-resistant, alkali-resistant, anti-crash |

| place of origin | China |

| Warranty | 3 years |

| OEM | yes |

| ODM | yes |

| Payment, delivery & Shipping | |

| payment term | T/T, 30% deposit, balance before shipment |

| delivery time | ready stock within 3 days. OEM within 15-20 days. |

| delivery port | Ningbo, Huangpu |

Black color:

Blue color:

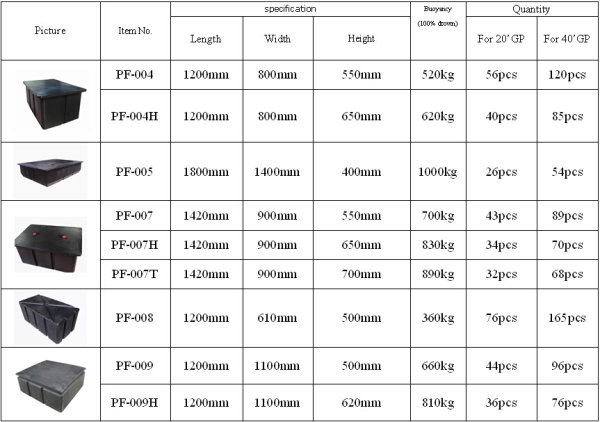

Different sizes:

By introducing world-class advanced automatic rotomolding equipment, we are able to produce a wide range of rotational moulding (rotomolding) product such as water tank, oil tank, chemicals storage tank, water tower, barrel, buoyancy tank, insulation case, water horse ( road barrier ), garbage cart, plastic pallet, plastic chair, children's slide, etc, and any other object that the injection moulding and blow moulding are unable to do, can all be produced by rotational moulding ( rotomolding).

Benefits of Plastic Rotomolding

•Custom roto-molded costs are significantly less than other custom plastic molding processes.

•The rotational molding process allows for quick turnaround from concept to production.

•Roto Molding does not force plastic into a shape. Forced air molding makes uneven, low-quality products. Rotomolded plastic products are even and durable.

Custom Rotational Molding for Plastic Product Designs

Roto molding is the best solution for plastic prototype molding. Not only is the rotomolding process cost-effective, rotationally molded plastic comes in all shapes and sizes. Any concept is valid, large or small, and can be produced in large or small quantities.

Factory:

500mm tihckness:

|

|